DESIGN

Considering customer demands and fashion trends, thanks to the years of experience and keen insights of professional designers and engineering teams in industrial product design, countless inspirations are generated and brought to life. The use of appropriate raw materials and prevailing colors is indispensable.

RESEARCH AND DEVELOPMENT

In addition to the inspirational concepts and design drawings, we attach greater importance to the creativity and innovation of the products. We utilize the variety of latest technology and equipment to achieve multiple 3D complex styles, which is important for the subsequent production steps. After having developed the 3D model, we reached an agreement, paving the way for the creation of prototypes.

PROTOTYPE

In order to turn drawings into truly feasible products, our highly skilled prototyping team chooses the most suitable colors and materials to produce a prototype to check whether the design goals have been effectively met. From the first prototype, we can clearly observe the rationality of each detail. Based on the prototype, we optimize the details and monitor the quality, such as the color of the glossy or texture, the comfort of wearing.

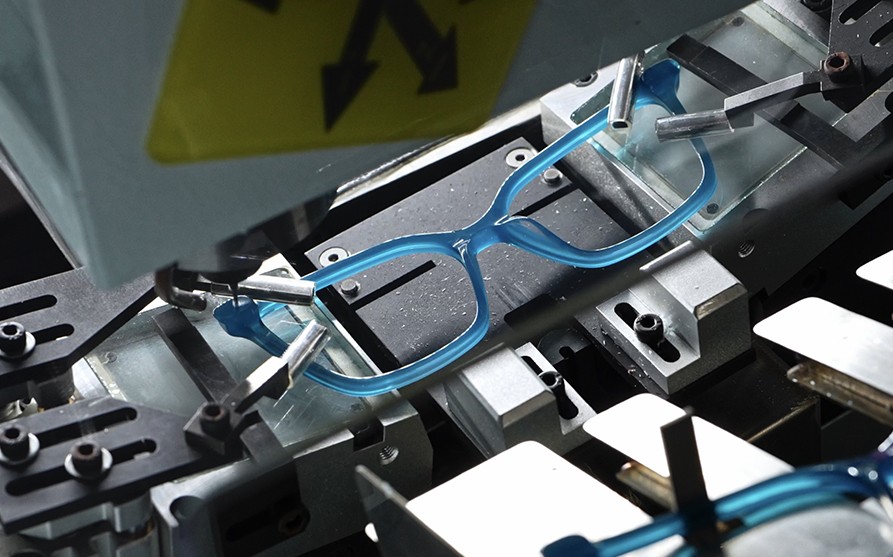

MANUFACTURING

After optimizing and enhancing accessories and materials in various product components, we will ultimately determine the prototype and put it into the factory for production. From the sourcing of raw materials to the allocation of the workshops, from the processing of semi-finished products to the packaging of finished products, our production process is subject to strict quality control measures to ensure the highest standards are maintained.

Eyewear Lab Testing

Artificial Sweat Test

The artificial sweat test is used to standardize the performance test of glasses under sweating conditions, simulate the physiological environment during human sweating, and evaluate the stability and durability of glasses under high temperature and high humidity conditions.

Weight test

Through the weight test, we can test the performance of the glasses under the condition of external tension. The purpose of the test is to determine the ability of the product to withstand the stress and the ability of the temple to deform and open.

Tension test

The tension test aims to determine the ability of various parts of the product to withstand tension, such as temple tips, nose pads, metal frames, etc.